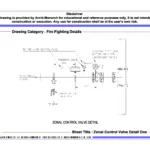

Alarm Check Valve Detail One

Downloadable Architectural Resources for Beginner Architects and Students

Alarm Check Valve Detail One

₹35.0 Original price was: ₹35.0.₹20.0Current price is: ₹20.0.

Hurry up! Flash Sale Ends Soon!

00

DAYS

00

HOURS

00

MINS

00

SECS

Related Drawings

Related products

-

Quick view

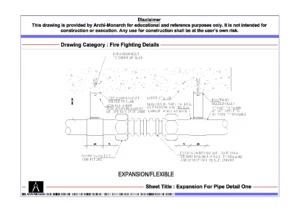

Expansion For Pipe Detail One

₹20.0Original price was: ₹20.0.₹10.0Current price is: ₹10.0. Add to cartAdd to WishlistAdd to Wishlist -

Quick view

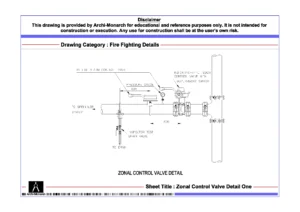

Zonal Control Valve Detail One

₹50.0Original price was: ₹50.0.₹35.0Current price is: ₹35.0. Add to cartAdd to WishlistAdd to Wishlist -

Quick view

Fire Fighting Schematic Diagram One

₹250.0Original price was: ₹250.0.₹199.0Current price is: ₹199.0. Add to cartAdd to WishlistAdd to Wishlist -

Quick view

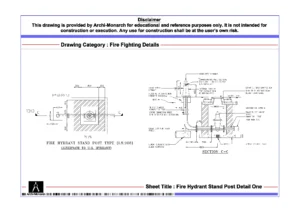

Fire Hydrant Stand Post Detail One

₹75.0Original price was: ₹75.0.₹49.0Current price is: ₹49.0. Add to cartAdd to WishlistAdd to Wishlist

Recently Viewed Drawings

-

Quick view

Dining Table Furniture One

₹50.0Original price was: ₹50.0.₹10.0Current price is: ₹10.0. Add to cartAdd to WishlistAdd to Wishlist -

Quick view

Toilet Water Supply Layout One

₹150.0Original price was: ₹150.0.₹125.0Current price is: ₹125.0. Add to cartAdd to WishlistAdd to Wishlist -

Quick view

Activity Room Detail One

₹350.0Original price was: ₹350.0.₹299.0Current price is: ₹299.0. Add to cartAdd to WishlistAdd to Wishlist -

Quick view

Toilet Water Supply Layout Twelve

₹125.0Original price was: ₹125.0.₹85.0Current price is: ₹85.0. Add to cartAdd to WishlistAdd to Wishlist

Reviews

There are no reviews yet.